UPONOR CUSTOMER SUPPORT

Frequently asked questions

FAQ

Filter FAQs:

PEX is an acronym for polyethylene (PE) that is crosslinked (X). It is a highly flexible, durable and non-toxic pipe for use in plumbing, radiant heating and cooling, hydronic heating and cooling, and fire sprinkler systems.

In 1968, German inventor Dr. Thomas Engel developed the method to chemically crosslink polyethylene, and in 1972, Wirsbo (now Uponor) introduced Engel-method PEX (called PEX-a) to the European market. In 1984, PEX-a was brought to North America initially for radiant floor heating and then for plumbing systems. Today, more than 17 billion feet of PEX is installed worldwide for heating, cooling, plumbing and fire safety systems.

Uponor PEX plumbing systems, branded Uponor AquaPEX®, have been in service since 1993.

Uponor PEX plumbing systems use flexible PEX pipe and innovative ProPEX® expansion fittings to create a solution that minimizes connections, resists corrosion, pitting and scaling, offers greater resilience in freezing conditions and lasts the life of the structure.

Uponor’s unique ASTM F1960 ProPEX connection method capitalizes on the shape memory of PEX-a. ProPEX connections use one simple tool to make fast, strong, solid connections that hold tight in strength tests with up to 1,000 pounds of force. ProPEX connections eliminate the need for torches, glues, solvents or gauges, and they cannot be dry fit, so there is never a question whether the fitting is made. ProPEX connections are available in both lead-free (LF) brass as well as engineered polymer (EP).

Making a ProPEX connection is simple: just place an expansion ring on the end of the pipe and use an expansion tool to expand the pipe and ring. After expanding, insert the larger-diameter fitting. As the pipe and ring shrink back down, it creates a solid, strong connection. In fact, ProPEX connections are the only PEX connection method that actually get stronger over time.

Yes, there are three different manufacturing methods for producing PEX crosslinked to varying degrees. PEX-a uses the Engel method which creates piping crosslinked to 80% or more. PEX-b uses the Silane method for piping that is 65 to 70% crosslinked. PEX-c uses the radiation method to create 70 to 75% crosslinked pipe. The higher the crosslinking, the more flexible and durable the piping.

Crosslinking relates to the molecular bond inside the pipe. The higher, more uniform crosslinking in Uponor PEX-a pipe means a more durable, flexible and damage-resistant pipe with faster, stronger expansion connections that hold tight.

· Kink reparability

· Tightest bend radius

· Superior resistance to stress-crack corrosion

· No micro-cracking during expansion

· Proven by Plastics Pipe Institute (PPI) Technical Report TR-52 for exceptional resiliency in freeze/thaw cycles

· Flexible for fewer connections

· Tight bend radius

· No joining glues, solvents or chemicals

· Visual connections that can’t be dry fit

· Can be air tested

Because of its flexibility, Uponor PEX can bend with each change in direction, reducing the number of required fittings for faster installations and greater system performance. Uponor PEX will not corrode, pit or experience scale buildup, and its ability to expand and contract offers greater durability in freezing conditions. Also, because you have to first expand the pipe and expansion ring to make a ProPEX connection, it is impossible to dry fit that type of connection. Additionally, because Uponor PEX is not a traded commodity, it provides stable pricing (and helps avoid theft on the job site that often happens with copper).

Uponor AquaPEX pipe and ProPEX fittings are available in sizes up to 3".

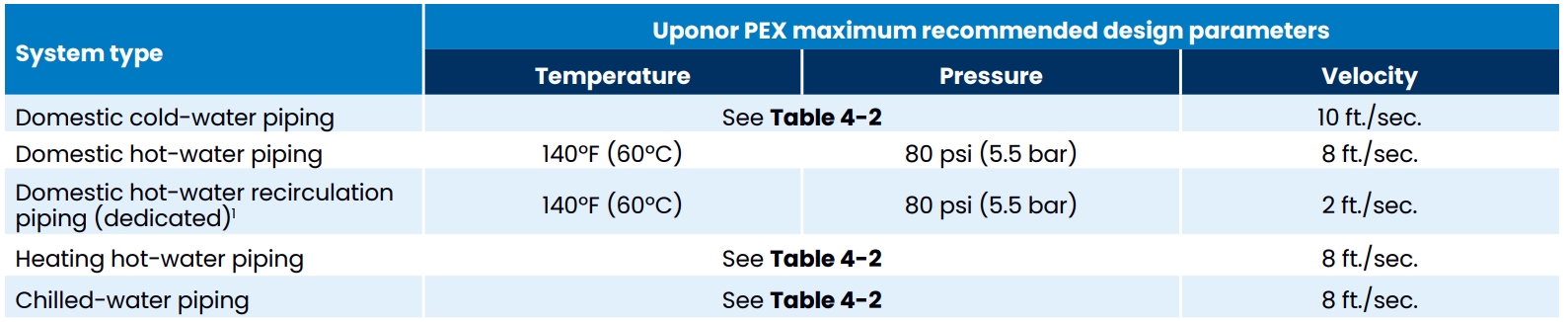

Uponor PEX is rated for the following temperatures and pressures:

· 200°F (93.3°C) at 80 psi (5.5 bar)

· 180°F (82.2°C) at 100 psi (6.9 bar)

· 120°F (49°C) at 130 psi (9 bar) (½" to 2" Uponor AquaPEX® white pipe only)

· 73.4°F (23°C) at 160 psi (11 bar)

For plumbing system operation, maximum temperature and pressures should not excess 140°F (60° C) and 80 psi.

In accordance with ASTM F876, the minimum hydrostatic burst pressure for PEX pipe at 73.4°F (23°C) is 480 psi for ½" pipe and 475 psi for ¾" pipe and larger. Uponor PEX-a pipe undergoes extensive quality testing daily to ensure it exceeds the ASTM F876 industry standards for burst pressures and consistently tests to nearly double the burst pressure requirement.

Uponor PEX-a pipe expands at a rate of 1.1" (27.94 mm) for 100 ft. (30.48 m) of pipe for 10°F (5.56°C) temperature change. Using PEX-a Pipe Support with struts, strut clamps, clevis hangers or loop hangers will help control the expansion/contraction of the pipe to levels similar to that of copper pipe.

Yes, Uponor PEX has undergone decades of rigorous testing. In 1973, Uponor (Wirsbo) submitted PEX pipe samples to an independent laboratory. For three decades, these samples underwent continuous hydrostatic tests at extreme temperatures and pressures — up to 203°F (95°C) and 239 psi (16 bar). At the conclusion of the tests, not a single piece of Uponor PEX experienced any breakdown or failure.

Plumbing systems use Uponor AquaPEX pipe while radiant floor heating systems typically use Wirsbo hePEX™ pipe, which features an oxygen-barrier layer to protect ferrous components in the radiant system.

The bend radius of Uponor PEX is six times the outside diameter of the pipe.

Yes, due to the pipe’s thermal memory, you can repair a kink with a shot of heat from a heat gun. Note this is only possible with PEX-a pipe. You cannot repair kinks in PEX-b or PEX-c pipe.

All PEX manufacturers are required to test their pipe’s resistance to hot, chlorinated water and list the PEX designation on the pipe’s print stream. Uponor PEX-a pipe meets the highest requirement for chlorine resistance at end-use conditions 100 percent of the time at 140°F (60°C).

Uponor AquaPEX white pipe has a one-month UV resistance. Uponor AquaPEX red and blue pipe have a six-month UV resistance.

Uponor AquaPEX pipe and ProPEX fittings are ideal for use in a variety of plumbing applications, including in-slab, underground, risers, mains, in-suite and graywater applications.

· Uponor AquaPEX red for hot-water potable plumbing

· Uponor AquaPEX blue for cold-water potable plumbing

· Pre-sleeved Uponor AquaPEX for in-slab plumbing

· Pre-insulated Uponor AquaPEX to meet energy codes

· Uponor AquaPEX reclaimed water pipe for graywater (reclaimed water) systems

Uponor Logic is a plumbing design and layout that maximizes the flexibility of PEX pipe to reduce connections while incorporating multiport tees located near fixture groupings to limit the amount of pipe and connections needed and improve installation efficiencies. This installation method uses considerably less pipe than a home-run layout, with just a few more connections, and it requires significantly fewer connections compared to a trunk-and-branch installation.

An Uponor Logic design uses a main line going to a multiport tee with distribution lines going out from the tee. These individual lines extending from the single multiport tee provide water to all fixtures in a single or adjacent grouping.

A multiport tee is a long, engineered polymer tee with multiple outlets. However, they are not classified as a manifold, so there is no requirement for access behind a wall. Multiport tees greatly reduce connection points due to their ingenious design. For example, six regular tees require 18 connections, but a flow-through multiport tee with six outlets only needs eight connections (six connections for the ports, a main flow-through inlet and a main flow-through outlet). Additionally, multiport tees require much less space to install.

Yes, Uponor has ProPEX water meter fittings and valves for direct connection to water meters sized ⅝" to 1".

Yes, Uponor offers a comprehensive line of lead-free (LF) brass press fittings, sweat fittings, threaded fittings, stub-outs, valves and wall boxes that meet lead-level criteria at or below 0.25% by composition and exceed the United States Safe Drinking Water Act.

No, Uponor PEX pipe and EP fittings do not contain any lead.

To insulate connections when installing Uponor AquaPEX pipe, simply pull the insulation over the ProPEX ring, leaving only the fitting body uninsulated. If fitting insulation is necessary, insulation kits are available in the industry.

• 12" (0.3m) away from standard recessed light fixtures*

• 2" (51mm) away from insulation contact (I.C.) rated fixtures*

• 5 ft. (1.5m) away from florescent lights*

*Unless insulated with suitable insulation

Support PEX with the same copper tube size (CTS) pipe hangers or supports used for metallic pipe. For 1" and smaller PEX, horizontal support spacing is 32"; for 1¼" and larger PEX, it is 48". (Note that some codes, as well as the National Plumbing Code of Canada, only allow for 32" horizontal support spacing regardless of pipe size, so be sure to check local codes for verification.)

Maximum support distance is 8 ft. (2.4m) for all pipe sizes. Support fittings 1½" and smaller within 12" (0.3m). Clamp the pipe at a maximum of 32 ft. (9.7m).

For all pipe sizes, support Uponor PEX pipe every 5 ft. (1.5 m) in vertical applications.

For cold-water risers, use a CTS clamp at the base of each floor as well as a clamp at the top of every fourth floor. For domestic hot-water risers, clamp at the base of each floor and the top of every-other floor.

Uponor PEX pipe is approved for direct burial in soil or concrete. For faster, easier installations, use Pre-sleeved Uponor AquaPEX pipe. The corrugated sleeving provides added protection for installations in concrete slabs or soil.

Yes, you can bury pre-insulated Uponor AquaPEX provided the pipe is away from contact with groundwater. Although the water will not compromise the integrity of the pipe or insulation, it will have a detrimental effect on the insulating value of the insulation.

Uponor ProPEX EP fittings are approved for direct burial. If using brass fittings, cover with a minimum 6-mil poly wrap.

For residential applications: Use a mixture of water and air (or air when allowed by local code), and pressurize to 25 psi (1.7 bar) above working pressure, or 100 psi (6.9 bar).

For large commercial applications: Fill the system with potable water, air or a combination of both. Then, condition the pipe to 1.5 times the test pressure or 120 psi (8.2 bar) for 30 minutes. After 30 minutes, release excess pressure until you reach desired test pressure [80 psi (5.5 bar) recommended].

- PLUMBING

- RADIANT HEATING AND COOLING

- HYDRONIC

- FIRE SAFETY

- ECOFLEX

- HOMEOWNERS